Question:

Read through the information below developing an understanding of how a tree works. In your own words explain the life cycle of a tree and how is it similiar to humans?

Understanding trees used in construction

Understanding the tree

Tree Parts

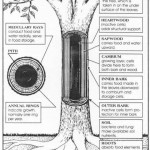

- Crown is part of the tree that consists of the leaves and the branches at the top of a tree.

- Leaves food factories of the tree. The leaves contain chlorophyll which gives leaves their green color and is responsible for photosynthesis. During photosynthesis, leaves use energy from the sun to convert carbon dioxide from the atmosphere and water from the soil into sugar and oxygen. The sugar (which is the tree’s food) is either used or stored in the branches, in the trunk, or in the roots. The oxygen is released into the atmosphere.

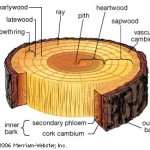

- Trunk (Stem)—supports the leaves and the branches of the tree and also contains the xylem, the cambium, the phloem, and the heartwood.

- Heartwood—inner core of dead wood that supports the tree. As a tree grows, older xylem cells in the center of the tree become inactive and die, forming the heartwood.

- Sapwood (Xylem)—the youngest layer of wood that transports water and minerals up the tree to the branches and the leaves.

- Cambium—the growing layer that is only one to two cells thick. It makes new cells during the growing season that eventually become part of the phloem, part of the xylem, or more cambium. The cambium is what makes the trunk, branches, and roots grow larger in diameter.

- Inner Bark (Phloem)—carries nutrients and sugar from leaves down the tree to its branches, trunk, and roots.

- Outer Bark—protects the tree from injury, disease, insects, and weather.

- Taproot—long main root that anchors the tree and absorbs water and nutrients from deep in the soil. It helps to support the tree. (Not all types of trees have a taproot.)

- Lateral Roots—underground roots that get smaller and smaller. They take in water and nutrients and help to support the tree. (All trees have lateral roots.)

- Annual Tree Rings—records the tree’s age. Every year a tree grows a little more and a new tree ring is made.

Question:

List common characteristcs of trees, then using past knowledge of trees describe where you may have seen these types of trees?

Softwood and Hardwood

The terms softwood and hardwood do not refer to the density of the wood, but rather the type of tree that the wood comes from. Hardwood comes from angiosperms and softwood comes from gymnosperms. Therefore, the porous and easily scored balsa is hardwood but the dense and hard to work yew is softwood.

- Trees produce flowers

- Fertilization takes place through pollination of these flowers by birds and insects

- Mature seeds are encased in a nut or fruit

- Generally deciduous – looses leaves annually

- Leaves are often broad and flat

- Grow in temperate and tropical climates

- Slower growing and therefore denser

- Different varieties are mixed throughout a forest tract

Some common varieties:

- Maple

- Mahogany

- Balsa

- Elm

- Oak

Characteristics of softwood

- Trees produce cones

- Fertilization takes place when cones emit pollen into the wind

- Mature seeds are inside the cones

- Evergreen – keep their leaves all year round

- Leaves are thin and needle-like

- Grow in temperate and cold climates

- Quick growing and therefore generally lighter

- Often grow in large, single-species tracks

Some common varieties:

- Redwood

- Cedar

- Pine

- Fur

- Spruce

Common Uses for Hardwoods

- Hardwood flooring

- High quality furniture

- Boat-building

- Wooden toys

- Fixtures, fittings, and moldings

Common Uses for Softwood

- Wood turning

- Outdoor decking (redwood)

- Outdoor cladding, siding

- General construction, building frames

How old is that tree??????

How old are these trees? Count the rings to determine how old each tree is.

Mobot.org, retrieved March 31,2011 http://www.mobot.org/education/documents/Trees_Demystified.pdf

Milling Lumber

http://www.woodweb.com/knowledge_base/Milling_lumber_from_logs.html

Reference

Difference between.net (2006) Difference between Softwood and Hardwood Retrieved March 31, 2011, from: http://www.differencebetween.net/miscellaneous/the-difference-between-softwood-and-hardwood/#ixzz1IJg8YDJh

Mobot.org, retrieved March 31,2011 http://www.mobot.org/education/documents/Trees_Demystified.pdf

Common Wood Defects

Wood is far from a stable, consistent material. One of the biggest challenges of woodworking is learning to work within the constraints of a wood’s properties. But before you can expect to work within these constraints you must understand them. It is for this reason we present you with the following article, Common Wood Defects.

|

Wood Defect |

Features |

Caused By |

Effect |

Solution |

|

Blue Stain |

A bluish gray discoloration on the woods surface. This feature is most common in woods like Holly, Pine, and Sycamore. | Mold that grows in warm and moist area, usually poorly ventilated. | Discoloration of wood. | Can be cut off, placed out of sight, or concealed with a dark stain. |

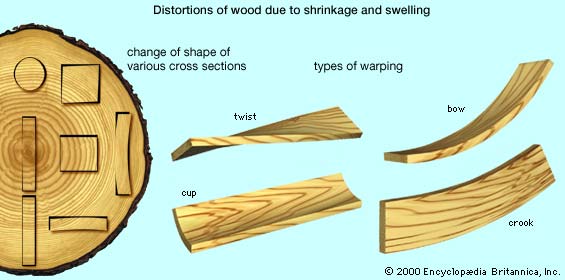

| Bow | A curve along the face of a board that usually runs from end to end. | Improper storage. Usually moisture evaporation from one side and not the other. | Stock is difficult to work with and cut. | Cut in to smaller pieced, even out on a jointer, or nail (screws are better) in place with bow bulging out. |

| Checks or SplitsPicture | Breaks at the end of a board that run along the grain. Checks and splits are usually restricted to the end of a board. | Rapid Drying. | Can effect the strength and appearance of the board. | Should be cut off or worked around. |

| Crook | Warping along the edge from one end to the other. This is most common in wood that was cut from the center of the tree near the pith. | Can be caused by improper drying and storage or the presence of reaction wood. | Can be difficult to work with. | The higher spots can be cut away on a table saw or jointer using a special jig. |

| CupPicture | Warping along the face of a board from edge to edge. This defect is most common of plain-sawn lumber. | This defect can be caused when one board face dries at a faster rate than the other. | Stock can be difficult to work with. Trying to “force it flat” can cause cracking along the grain. | You can try allowing the board to dry at the same moisture content under pressure, rip it into smaller pieces on a table saw, or use a jointer to remove the high spots. |

| Dead or Loose KnotPicture | A dark, usually loose knot. | This is caused by a dead branch that was not fully integrated into the tree before it was cut down. | Can mar the appearance of the wood, fall out, become loose, or weaken stock. | Should be cut out, around, or glued in place and filled with a wood putty. |

| Gum, Sap, or PitchPicture | Accumulations of a resinous liquid on the surface or in pockets below the surface of wood. | Injury to the tree. | May cause difficulty when finishing. | Should either be cut off or scraped out and filled. |

| Machine Burn | Dark streaks along the face of a board. | Usually caused by planer blades that are dull or spun on a part of the board for too long. | Discoloration to the surface. Sometimes the burn can penetrate into the board. | Can be sanded off or cut down with a jointer. The depth of the board often determines the amount of work needed. |

| Ring Check | Breaks in the wood along the annual growth rings. | Improper drying or damage during transport. | Can effect strength or appearance. | Should be cut around, place out of sight, or glued down. |

| Tight KnotPicture | A know which is tightly integrated into the surrounding wood. | This was once a branch that was incorporated into the tree as its girth increased. | Does not effect the lumber’s strength. | May be removed for appearance purposes. Some lumber such as Knotty Pine, is highly prized for this feature. |

| Twist | Warping in lumber where the ends twist in opposite directions. (Like twisting a towel) | Growing conditions, uneven drying or the presence of reaction wood. | Can be difficult to work with. | Can be cut into shorter boards or the high spots can be removed on a jointer. |

| WormholesPicture | Small holes in the wood. | This is caused by insects boring through the wood. | Can be used to simulate old or wormy wood. | Cut around worm holes or uses as is for decorative purposes. Be sure the insects are dead |

Very informative post.

Nice math/science connection here as well: looking at tree rings for determining age of a tree and exploring the effects of climate change.

See: http://www.ecokids.ca/pub/eco_info/topics/climate/treerings/index.cfm

This site from the Arbor Day Foundation ties nicely in with what you’re doing:

http://www.arborday.org/kids/carly/lifeofatree/

Greg I like the sites you sent, they were alot more interactive then the video I found.

I can feel you pain George it was really difficult for me as well to create my blog and add the picture and video. I really like your blog is very informative, I really like your site in general. Good luck and I look forward to working with you.

I can feel you pain George it was really difficult for me as well to create my blog and add the picture and video. I really like your blog is very informative, I really like your site in general. Good luck and I look forward to working with you.

I really liked your post about trees. I did not know that a tree had so many layers. Thats why I loved this bloging experience becuase we can learn from each other.

http://www.extension.iastate.edu/publications/pm1374a.pdf